vivo Tokyo R&D Centre: How vivo approaches global camera tech development

28. February 2022

vivo's Tokyo R&D Centre is advancing smartphone imaging technology two years ahead in time

• Building on Japan's history of imaging development that spans more than a century

• Utilizing local resources and joint research with local higher education institutions

• One of ten vivo global R&D centres located around the world

It was in 2017 when vivo advocated that future smartphone technology research would no longer be limited to technological breakthroughs in a single area, but rather focus on overall technological innovation, following the approach that each smartphone should be more than just the sum of its parts. The vision behind the company's strategy paved the way to make full use of valuable resources in different parts of the world, by conducting a plethora of research and development efforts. The setting of the Tokyo R&D centre is, in a way, the essence of vivo's global R&D strategy.

The primary functions of the vivo Tokyo R&D Centre are to focus on pre-research of new and emerging camera technology, which will be used in two years' time, and to advance prototype development and commercialization in coordination with the vivo headquarters. The establishment of the Tokyo R&D centre was essential for vivo - "Japan has more than a 100 year history in imaging development, and has undergone a huge transition from cellulose film to digital imaging - including advancements in lenses, sensors, and motors," highlights Mr. Masazumi, Chief Expert at the vivo Tokyo R&D centre. "Mobile camera technology – including smartphone imaging – can only be developed on the foundation of a robust and mature imaging industry, which is precisely the biggest advantage of the location of the Tokyo R&D centre."

As the Tokyo R&D centre grew, it was relocated from Shimbashi to Gochome, Chuo-ku, the central area of Tokyo. This is the busy area of the city, which is home to imaging tech, and during the years gradually expanded research focus from imaging as we know it, to niche areas such as automotive cameras, sports cameras, and industrial cameras – all which plays benefit to "spill over" of sorts, improving smartphone imaging development. "Recently, imaging devices have been widely used in industrial fields such as robotics or medical treatment – for example gastroscopes. In this sense, imaging devices are prevalent in multiple fields in Japan", Mr Masazumi adds. These technologies have not yet fully emerged in vivo's home market of China, but as with the launch of the vivo signature gimbal camera and the completion of the vivo global manufacturing bases, the successful application of benefits from the above technologies are well worth looking forward to.

Challenges in developing new tech in a period of pandemic

However, R&D centres around the world also face challenges. For example, while transitioning from R&D to mass production, prototypes, which are subject to continuous testing and improvement, need to fit into products manufactured in China. From research to mass production, the key lies in successful prototyping where results can be generated from simulation tests, to create optimised prototypes. By repeating this process and making continuous adjustments, perfecting, finetuning and debugging, new technologies can be adjusted to work perfectly with various categories of products.

Another challenge for the R&D Team in Tokyo was the fact that Japan and China follow different smartphone hardware specifications. As a viable solution, experts from the Tokyo R&D centre recommended utilizing locally unique resources for R&D, by proactively seeking joint R&D with local higher education institutions, while actively collaborating with the headquarters back in China. "Japan has many excellent suppliers, manufacturers, partners and universities. It is more efficient to tap into local resources," explains Mr. Masazumi, adding "This is one of the strategies that helps us at the Centre in solving various future challenges."

However, R&D centres around the world also face challenges. For example, while transitioning from R&D to mass production, prototypes, which are subject to continuous testing and improvement, need to fit into products manufactured in China. From research to mass production, the key lies in successful prototyping where results can be generated from simulation tests, to create optimised prototypes. By repeating this process and making continuous adjustments, perfecting, finetuning and debugging, new technologies can be adjusted to work perfectly with various categories of products.

Another challenge for the R&D Team in Tokyo was the fact that Japan and China follow different smartphone hardware specifications. As a viable solution, experts from the Tokyo R&D centre recommended utilizing locally unique resources for R&D, by proactively seeking joint R&D with local higher education institutions, while actively collaborating with the headquarters back in China. "Japan has many excellent suppliers, manufacturers, partners and universities. It is more efficient to tap into local resources," explains Mr. Masazumi, adding "This is one of the strategies that helps us at the Centre in solving various future challenges."

vivo's blueprint for the future with consumer needs at its core

In vivo's corporate culture, being user-oriented remains the main principle guiding the company's R&D work. Whether it is the gimbal camera or the V1 imaging chip, these are all based on vivo's insights and overall review of consumer needs. The planning/product team in China analyses future research trends of smartphone imaging based on user feedback. This information is then shared with the Tokyo R&D team.

With this process, Mr. Masazumi realized that the demands of consumers around the world are sometimes quite similar. "Chinese as well as global consumers have higher expectations of high-definition imaging, but there is less space left for the lens module within the phone itself with every new generation." Given this contradiction, Mr. Masazumi believes that one major direction of future imaging hardware development will be to make it "miniaturized and integrated". He further explains: "Camera lenses now are generally assembled. In the future, they might all be integrated into one piece, with sensors that offer greater light sensitivity and faster data throughput."

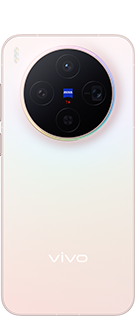

By further investing in research, vivo established ten R&D centres in ten different locations: Shenzhen, Dongguan, Nanjing, Beijing, Shanghai, Hangzhou, Xi'an, Taipei, San Diego and Tokyo. These centres focus on the development of cutting-edge consumer electronics technologies and services, including 5G, artificial intelligence, industrial design, imaging systems and other up-and-coming technologies many of which will be implemented in upcoming vivo products. In the future, vivo hopes to embrace further market environments to expand its global R&D layout and continue providing innovative products and services that are tailored to customers' needs.